#1 mm laminate

Explore tagged Tumblr posts

Text

8278 SF Brown Walnut - 0.8 mm PVC Laminate Sheet | Amulya Mica

Explore the 8278 SF Brown Walnut, a premium 0.8 mm PVC laminate sheet from Amulya Mica. Perfect for enhancing interiors with its rich walnut finish. Durable and stylish solution for modern spaces.

#0.8 mm laminate#pvc laminate sheet#Best Laminates in India#pvc laminate#latest mica design#laminate designs#premium laminates#1 mm laminate#latest laminates design#advance pvc laminate#buy laminates online

0 notes

Text

1 mm laminate price

Ogaan Laminate offers premium quality 1 mm laminate at competitive prices, ideal for a variety of interior applications. Known for its durability, stylish designs, and easy maintenance, Ogaan’s 1 mm laminate is perfect for residential and commercial projects. Contact us for the best 1 mm laminate price in the market.

0 notes

Text

1 mm Laminate - Shop Online exclusively for high-grade 1mm laminate at affordable rates in India | Frikly

Looking for high-grade 1mm laminate in India? Look no further than Frikly! Shop online now for exclusive deals on high-quality laminate at affordable rates. Don't miss out, COD, Free Delivery, fast delivery and excellent customer service. visit us today!

https://frikly.com/category/laminates/1-mm

#1 Mm Laminate Price#1 Mm Mica Sheet Price#1 Mm Sunmica Sheet 8x4 Price#Laminate 1 Mm Price#1 Mm Sunmica Price#1 Mm Mica Price#1mm Pvc Laminate Sheet Price#1 Mm Sunmica Sheet Price#1mm Laminate Sheets Price#sunmica sheet 8x4 price 1mm

1 note

·

View note

Text

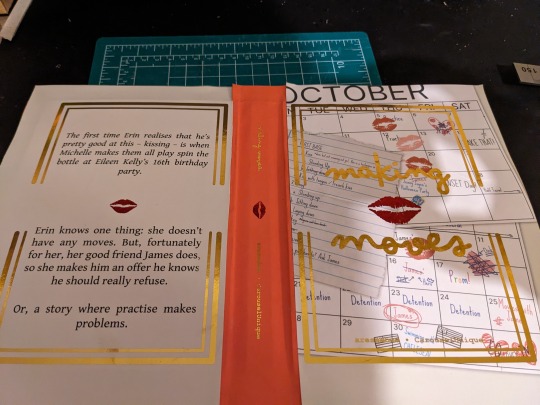

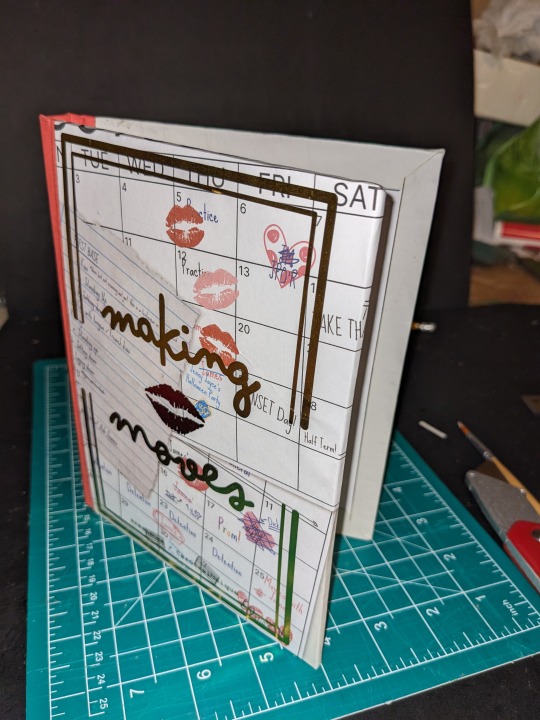

Bound: Long Haul by @wolfpants

As a writer, I often am fondest of my shorter stories, but these fics are not the obvious choice for binding because they're so little. I actually started setting this story a while ago but put the typeset aside when I realized it was going to be such a low page count.

But more recently, I have been experimenting with a pamphlet bind to see if short stories and/or text blocks can be bound to my satisfaction, and yep! They can!

I love this short story by wolfpants and I have read it often enough that it deserved to be bound and put in my library. The story contains lovely delicious smut and (as you'd expect from wolf) excellent character-building, dialogue, and just exactly the right amount of realism. Wolf writes true adult characters and I adore this about their writing.

More about process and materials under the cut!

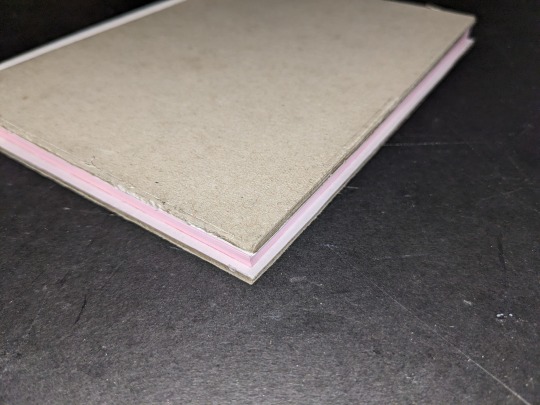

Materials: This is a quarto letter pamphlet bind using letter-sized 24# paper. The end papers are chiyogami acquired in Montreal. Book boards are actually cut from matte board that came in some packet of supplies or another, about 1 mm thickness and quite a bit bendier than my usual 2 mm book board, but worked nicely and feels appropriate for this little baby.

Book cloth is wooqu off Amazon as per. I sewed the pamphlet using three strands of waxed embroidery floss. Spine is strengthened with mull and a little strip of the same paper as the text block. Cover decoration is HTV vinyl. A few titles are foiled with toner-activated foil and a laminator. (Big shout-out to @sits-bound for technical assistance with figuring out that process!)

Process: This is a sewn 64-page/16 sheet quarto. I followed DAS Bookbinding's YouTube video here pretty closely except (as you can see) I went for a full cloth bind. I also added the paper layer on the spine before wrapping in cloth. I did this because I found mull alone — at least my cheap-ass mull — was not making for a smooth spine. The paper was a huge help on this front.

This is actually my third attempt at this style of binding (not counting the versions I did in class under adult supervision) so please do not be too impressed, lol.

The whole thing is held together by 50/50 corn starch/PVA mix (as well as the thread.)

I trimmed the tail twice by accident so then I had to trim the head twice too, and so that's why my margins are slender. :D

The HTV decoration was designed by yours truly (if you look at it for very long you'll be like "oh yeah I can see that" ahahaha) but I was really pleased with how it came out. I think I'm FINALLY finding my successful approaches for applying HTV. And yes, it was a monumental pain in my ass to weed. Worth it!

Peep the grease mark on the front title page. Sexy. No idea where it's from but yowza.

Bind short fic! Short fic also deserves binding! *steps off soapbox*

150 notes

·

View notes

Text

Lakeside

Summary:

James Sunderland doesn't remember why he'd driven his car into the lake. He can't explain why he was rescued, or what led to his decision, but he clings to the hope that someone will help him piece it together before hell freezes over. Douglas Cartland swore he'd never set foot in that godforsaken town again. That vow gets tested when Toluca Lake begins freezing in the middle of summer, against all logic and reason, and resurrects the drowned man he'd given up for dead.

Or, "Nature is healing. Hell is freezing over."

Prologue - Tumblr / AO3

1.

Will you reach heaven unassisted? Or must corpses point the path, Blind eyes glimpsing gold?

Another face swims in.

"Mr. Sunderland: Dr. Takuma again. I know how worn out you must be from the tests you've endured today. Rest assured, we won't keep you for much longer. Before we let you go, though, there is one last thing we must test."

"I need to go home."

"This will move much faster with your cooperation."

The laminated card clipped to the breast pocket claims his name is Robert Takuma. When James observes his face, he sees no connection. Certainly there are pieces that constitute an identity, eyes, nose, and mouth, but no underlying thread stitches them together. They float in a loose amalgamation without coherence or meaning. A mannequin of clothed limbs perches on the stool before him.

"Now, this exercise may seem rather silly and childish on the surface, but it will reveal quite a bit about the nature of your condition. With these flashcards, I will show you a series of illustrations. You tell me which is correct about them. Ready?" He interprets James' silence as consent and raises the first card. "Man or woman?"

James dwells in wordlessness before murmuring, "Woman."

"Why?"

"It's wearing high heels."

"Mm." The card settles in Takuma's lap, replaced by another. "Old or young?"

"Old."

"Why?"

"Cane."

"Good." Hands shuffle the deck. "Blonde or brunette?"

Silence.

"Blonde or brunette, Mr. Sunderland?"

"…I don't know."

"We'll circle back to that," Takuma says. "Which of these is not wearing glasses?"

He chooses the left.

"Point to the figure with a green shirt."

He complies.

"Heart tattoo on the bicep."

That, too.

"Smiling?"

They're treating him like a child.

"If you would, please list three differences between these faces."

He stares at the twin cards. They aren't illustrations but Polaroids. In his left hand, Takuma holds an enlarged facsimile of the photo he keeps in his wallet.

Kept; the lake stole it from him. Where Toluca's minerals leached its color and the water crumbled its grain to dust, the image burns clearly, seared into his mind by the radiant thuribles of the fluorescents burning around them.

In a world where most faces elude him, she shines, clear and lucent.

The other hand shows a horrendously different woman. Pustules swell and blister her complexion like globules of ancient film burning to a close. Melting into a wax grotesquery of herself, deprived of her outer beauty, never abandoning her smile.

The whisper crawls from his vocal cords. "Why do you have pictures of my wife?" A cold trickle forms on the back of his neck as the doctor rises. "No— Who gave you those?"

"Thank you for your time, Mr. Sunderland."

---

Damn it, what kind of game do they think they're playing? They've kept him penned in here for way too long. Locking him in a dim room like this, it's insane. More than insane. It's criminal. Mary's coming home tomorrow. He can't be languishing in the hospital himself.

Confined to a padded mattress, James glances down his arm. Gray, waterlogged skin bundles a loose blanket of flesh over atrophied muscles, showing veins and bones in disgustingly salient detail. Blue vessels weave a fine net over his flesh. IVs have blossomed grotesque bruises along its expanse.

Crushing his lips together, James tears the adhesive. The needle he extracts stings like hell, bringing a startling smatter of crimson to the surface.

Monitors scream, a noise he extinguishes by pulling the cord. No need to alert the nurses.

His head throbs as he wheels his bare feet onto the tile.

God, he's exhausted.

In the corner stands a bureau. Rising on unsteady knees, he shambles toward it.

Swinging the door open, he finds a bright silver square staring back at him. He opts to ignore it as he bends down to put on what remains of his clothes. They've taken his jacket, but at least the undershirt doesn't feel too damp when he slips his arm through the sleeve.

First things first. He's got to find a payphone and call his father. He doesn't want to impose on Frank, but he harbors a faint hope that he might have a spare key to their apartment so he can let Mary inside, allowing her to get settled in with her new nurse.

Hell, he'll pay, if that's what his father wants. Frank will protest anything for family; it's more to ease James' mind. He can't have Mary waiting out in the hall.

Tomorrow, he resolves. He'll straighten this out then. Tell his good Samaritans thank you even though he can't stay. Board a bus for North Ashfield.

The prospect of travel makes him nervous. Mary can hardly stand as it is, and… Well. St. Jerome's can't loan her a wheelchair her insurance won't cover.

She could lean on the wall, he supposes, try to slumber out his arrival, but can he gamble on the landlord allowing her to loiter there? Besides, her circulation's poor. Her hands and feet swell with fluid. Even though he finds himself sweating in this balmy air, she'd shiver.

His head sags on its neck. James indulges a new habit he's formed since being admitted and slowly, deliberately pops his knuckles one at a time. His hands have become skeletal, corded things he doesn't recognize; the water has eroded the muscle and fat that used to reside beneath the skin.

Air pockets crackle the joints as he depresses, with long, thin fingers tapering into chalk-white nailbeds. He doesn't feel them. These can't be his. These are borrowed from someone else, a pair of gloves he's forced to wear, coated in small nicks and gouges.

(woodgrain biting into his flesh when he grips the)

He raises his head to face his reflection.

They alleged this was his as well. All of these unsolicited gifts offered him, as though he had to be introduced as a guest to his own body.

The staff hadn't taken too kindly to his refusals. The first time, they insisted. The second, he grew agitated. Please put that away. He'd made his request clear after the numerous hours they'd spent poking and prodding him to ensure his mind remained intact. His patience had worn thin in worry over how long they were keeping him from Mary.

Wasn't a little disorientation after a car accident to be expected? How many more hoops did they want him to jump? He's healthy, isn't he?

(more than she'll ever be)

The third, he lunged to snatch the mirror from the nurse, but missed. Instead, he wound up knocking it out of her hand, accidentally shattering glass in the process.

James froze when the pieces scattered diamonds across the tiles. Disembodied parts flooded the floor. Eyes, lips, ears. Nothing adding up.

The moment he realized what he'd done, a shameful heat suffused his cheeks, pricking needles under his skin. Look at yourself, he thought, the irony of his inability only pushing the thorns deeper. You're acting like a child. What would Mary think?

James gives empty gaze to the glass, the impostor on the other side mirroring his languid movements. Watched by a mask he cannot remove. The eyes that track him aren't really his own. Two broken-bottle green irises. Not too deep. Too shallow.

Fingers uncertain, he traces the contours of this alien terrain, starting from the bridge of his nose downwards, into the dip of his Cupid's bow. The soft streams of breath he releases through his nostrils tickle him.

A thin sheet of epidermis stretched over musculature, bone, and cartilage. It feels too dead an inheritance to claim.

As he watches this strange reflection mimic his movements, he suffers a dark but fleeting impulse to harm it. If he hooked his dirty nails into the flesh and peeled away his doppelganger's false mask, shed his snake's skin layer by layer, there may be a chance he'd reveal something truer underneath.

(or maybe you would find nothing)

6 notes

·

View notes

Text

フェンダー編第458回:「Made In Japan FSR Traditional Late 60s Stratocaster GP -Mahogany Body&Neck!-ってこんなこと」

ギタープラネット限定販売の特注オーダー・モデル!! まるで「オール・ローズ」!? 有りそうで無かった、「オール・マホガニー・ストラトキャスター」が入荷しました!! 担当スタッフのこだわり多め、ラヴ多めの逸品です!! お見逃しなく!!

SPEC Body : Mahogany Body Finish : Satin Polyurethane Neck : Mahogany, “U” Shape Neck Finish : Satin Urethane Fingerboard : Round-Laminated Rosewood, 9.5 (241 mm) Frets : 21, Vintage Pickups : Fender Custom Shop Fat 60s STRAT PU ×3 Controls : Master Volume, Tone 1. (Neck Pickup), Tone 2. (Middle&Bridge Pickup) Hardware Finish : Nickel/Chrome Strings : Nickel Plated Steel (.009-.042 Gauges)

”Jimi Hendrixへ提供する為に製作開始されたものの、氏の逝去を以て行方知れずとなった伝説的なギター” としてギター・ファンの間で語り草となっている、1968年製オール・ローズウッド・ストラトキャスターからインスパイアされたデザインとなっています。 僭越ながら、カスタムショップ製品の横に並んでいても遜色無い!? と思える程にクールなルックスのみならず、 もちろんサウンドも、マホガニー・マテリアルに由来した”暴れるサウンド・フィール”が大変格好良いです!! 当店こだわりの特注オーダー・モデルを���ぜひこの機会にご検討下さい!!

/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/_/

GUITAR PLANET 2023

吉岡 哲志

https://www.guitarplanet.co.jp/

8 notes

·

View notes

Text

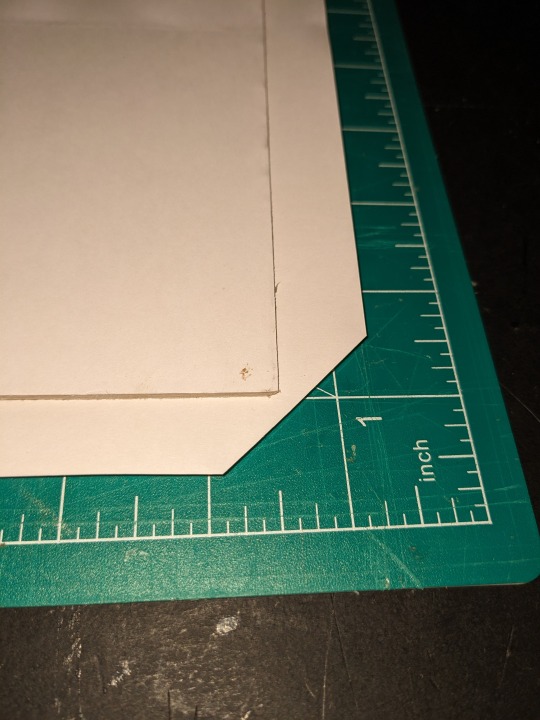

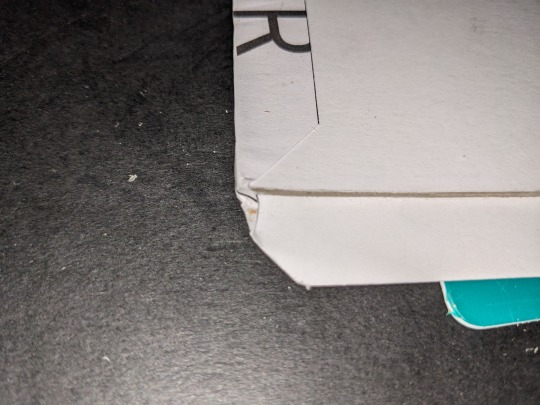

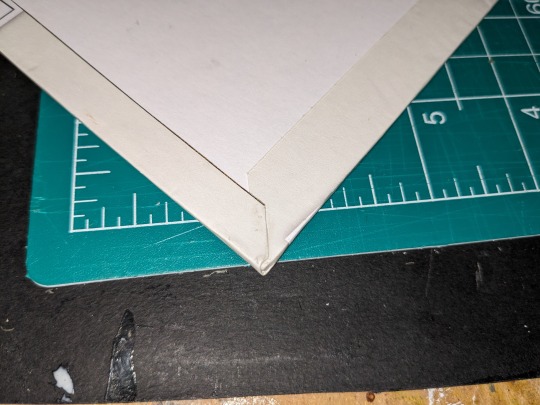

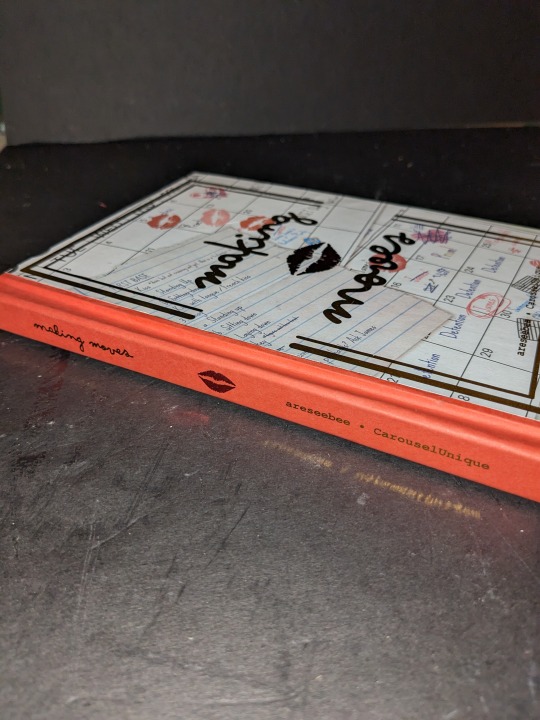

How I bind my fics - Part 3

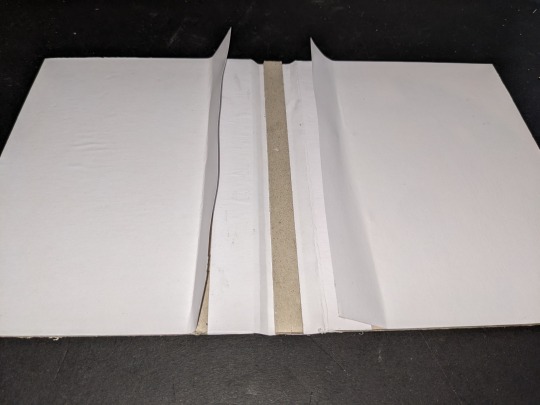

We ended part two with an assembled text block, which is perfectly functional as a book, but we're here for the hardbacks

Hardbacks start as greyboard for me, 3mm (1/8 inch), and we have to do a little maths to work out the size. We want a 3mm overhang around the top, bottom, and outside edge, which sounds simple (and it is for the top and bottom), but for the width we need to take a few mm away too, so the book can open flat. In this case, it ended up being 4mm narrower than the text block

We cut the cover and spine boards using our trusty L-ruler and knife, although sometimes I also score the line I want to cut and use the chisel

I like to make Bradel bound books, so we need to make a "hinge" for the spine to connect to the cover - the video explains it better than I could, but essentially it's a piece of thickish paper (120gsm) that we glue the boards to

We then need to line the inside of the covers, again with 120gsm paper, leaving about an inch unglued closest to the spine

These flaps are what the textblock's flaps will sit under later when we come to glue it up

It's starting to look like a book!

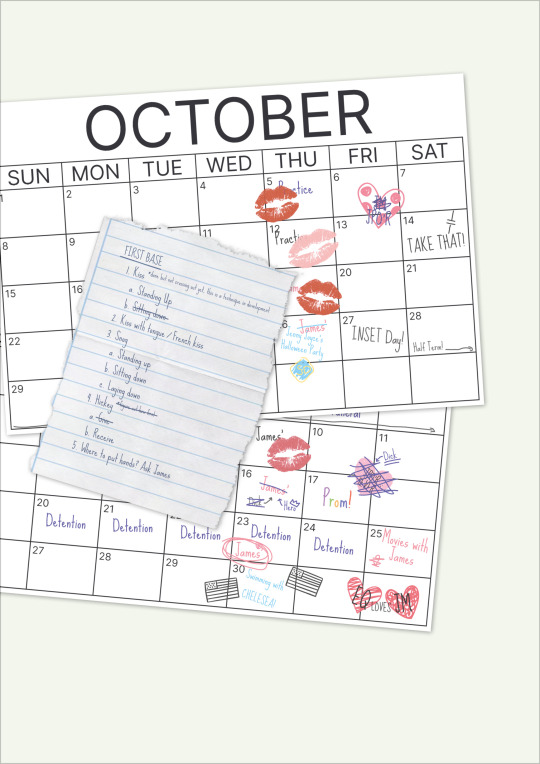

We can now move on to designing the covers. One day I'll get a A3 printer and be able to do full spread covers, but for now I break it into three - the front, the back, and the spine.

These are again designed in inDesign, and in this case I've made a background and a foreground for the front and back. This is because the backgrounds will be inkjet printed, and the foreground will be laser printed over top

(A higher res version of the cover background - I've tried to tally the fic to Erin's Diary, and hope I've shown Erin's personality a bit - there's a point when she stops labelling it a going to "Practice", and starts going to "James'"...)

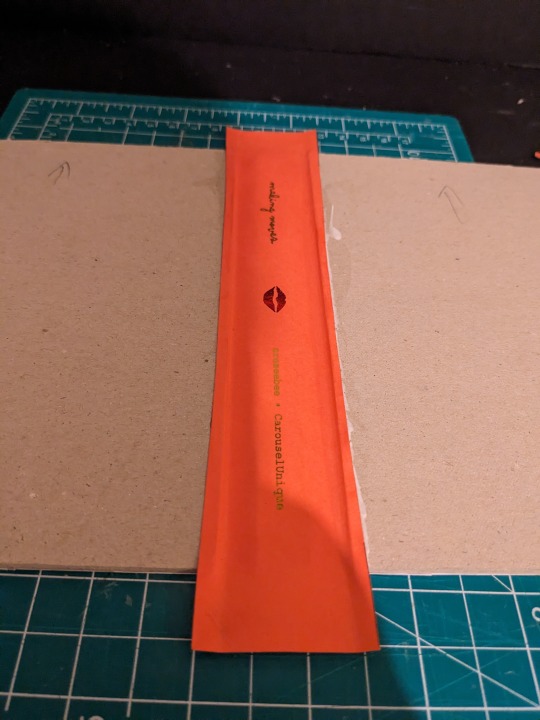

The spine is laser printed directly onto coloured 150gsm paper - slightly thicker, as this bit will be under the most stress of the cover

The reason we're laser printing over top is so we can use toner reactive foil - it'll stick to the laser print but not the inkjet one

It's simply a case of taping the foil sheets down tight over the areas we want to foil, masking areas we don't (although if you're doing two colours like we are, my experimentation says do them together), then feeding it through a hot laminator before peeling the foil sheet off

(ignore the masking tape - its on areas we're cutting off in a minute)

Next we're cutting and gluing these pages onto the boards - the little boxes you can see jutting out from the edges are registration marks so I can pencil in on the revese where to line up the boards - we use the bone folder again to smooth them out, work out any air bubbles, and to push the paper into the nooks and crannies

Now we need to cut the corners, using my handy-dandy 3D printed template

We cut them so that when we fold it over we get a nice crisp fold

On that note, we need to glue the edges and fold them over, making sure to get the glue right into the edge of the board

We're very nearly there now - just need to wed the textblock to the casing

We start by dry fitting the block in the case, then carefully opening one cover and gluing the tabs down, followed by the other, again smoothing with the bone folder

Finally, we need to carefully glue down the endpapers to the board (no matter how careful or which order you do them in, the front paper always gets a little messy for some reason)

Et voilà! We have a book - it'll live in the press overnight while the glue dries, but once it's ready it'll take it's place between "In Their Thirties" (which I'm tempted to rebind now I have foil for the cover), and "Vacation James"

tumblr

I'm sure there are seasoned bookbinders reading this going "No, you fool!", but I'm happy with the outcome. It's fun, and I love being able to have something in my hands at the end of it; I may not be able to draw fanart, but I can make something to show my love for my favourite creators!

Thanks again to @areseebee and @derrygirlstrash/@carouselunique for writing this really fun fic, and to @imstressedx for planting the notion in my head to do a step-by-step

Now, on to the next fic!

3 notes

·

View notes

Text

ABA and AB Blown Film Extrusion Machine in Odisha

Adroit Extrusion offers advanced ABA & AB Blown Film Extrusion Machines in Odisha designed to deliver superior-quality plastic films at an optimized cost. Our Manufacturing unit is based in Ahmedabad, Gujarat. These machines reduce raw material usage, enhance film strength, and offer versatile applications, benefiting the plastic industry. Our machines are compatible with LDPE, LLDPE, HDPE, CaCO3, and virgin materials, supporting various film types and applications. Features: Efficient Extruder Design: The single smaller extruder for A-layers produces 30-40% new plastic resins per minute, ensuring better material handling. The second extruder is for the intermediate layer, which utilizes recycled plastic resins and CaCO3, helping reduce overall production costs. Cost-Effective & Sustainable: The ABA three-layer blown film technology lowers raw material costs while still maintaining high plastic film quality. The design reduces material usage, and produces films 30% stronger than monolayers, enhancing product strength and value. Technical Specifications: Model Name: Duoflex ABA Three-Layer & AB Two-Layer CO-Extrusion Blown Film Plant Materials Used: LDPE, LLDPE, HDPE, CaCO3, Virgin Raw Materials Output Range: 60 - 200 kg/hr Screw Diameter: 35/45/55/65/75 mm (customized) Screw L/D Ratio: 30:1 (customized) Layflat Film Width: 500 - 3000 mm Thickness Range: 20 microns to 150 microns Applications: PE general-purpose films HDPE pick-up bags Shade-net films PE lamination films Mulch films Courier films Stretch & cling films Shrink films Anti-rust films Tarpaulin films FAQs: Q: What materials can be used in the ABA & AB blown film extrusion machines? A: The machines handle materials like LDPE, LLDPE, HDPE, CaCO3, and virgin raw materials, suitable for various film types. Q: What is the output capacity of the machine? A: The ABA & AB Blown Film Extrusion Plant outputs between 60-200 kg/hr, depending on the configuration. Adroit Extrusion is a Supplier of ABA and AB Blown Film Extrusion Machine in Odisha including location in Bhubaneswar, Cuttack, Rourkela, Berhampur, Sambalpur, Puri, Balasore, Bhadrak, Baripada, Angul, Balangir, Balasore, Bargarh, Bhadrak, Cuttack, Debagarh, Dhenkanal, Gajapati, Ganjam, Jagatsinghapur, Jajapur, Jharsuguda, Kalahandi, Kandhamal, Kendrapara, Kendujhar, Khordha, Koraput, Malkangiri, Mayurbhanj, Nabarangpur, Nayagarh, Nuapada, Puri, Rayagada, Sambalpur, Subarnapur, and Sundergarh. For more details or inquiries, feel free to contact Adroit Extrusion and explore how our ABA & AB Blown Film Extrusion Machines can optimize your production process in Odisha! View Product: Click Here Read the full article

#ABAandABBlownFilmExtrusionMachine#ABAandABBlownFilmExtrusionMachineExporter#ABAandABBlownFilmExtrusionMachineinGujarat#ABAandABBlownFilmExtrusionMachineinIndia#ABAandABBlownFilmExtrusionMachineinOdisha#ABAandABBlownFilmExtrusionMachineManufacturer#ABAandABBlownFilmExtrusionMachineSupplier#AdroitExtrusion#Ahmedabad#Angul#Balangir#Balasore#Bargarh#Baripada#Berhampur#Bhadrak#Bhubaneswar#Cuttack#Debagarh#Dhenkanal#Exporter#ExporterofABAandABBlownFilmExtrusionMachineinOdisha#Gajapati#Ganjam#Gujarat#India#Jagatsinghapur#Jajapur#Jharsuguda#Kalahandi

0 notes

Text

The VJ Instruments Advanced TDP & ODF Machine Pilot Scale Machine is an advanced solution for developing transdermal therapeutic delivery system laminates and edible films. With precise coating and lamination capabilities, it ensures high product quality and accuracy. The machine’s user-friendly design, temperature control, and observation features make it efficient for small-scale production. Operating with a balcony configuration, it coats a 150 mm wide web continuously, maintaining a thickness variation of ±1%. The drying process is facilitated by an electrically heated stainless steel plate, and evaporated solvents are efficiently removed by ventilators. The final product is a meticulously coated and laminated film, rewound for further use. The VJ Instruments machine stands out for its innovation, precision, and streamlined operation.

0 notes

Text

Is Gold Coast Floor Sanding Suitable for All Types of Wooden Floors?

Wooden floors are a timeless choice, admired for their natural beauty, durability, and warmth. Over time, however, even the most well-maintained wooden floors can lose their luster due to wear and tear. This is where gold coast floor sanding comes into play, offering a solution to restore and rejuvenate wooden surfaces. But is gold coast floor sanding suitable for all types of wooden floors? Let's delve into this topic to find out.

Understanding Floor Sanding

Floor sanding is the process of removing the top surface of a wooden floor using abrasive materials. This helps eliminate scratches, stains, and other imperfections, leaving behind a smooth and fresh surface ready for refinishing. The effectiveness of this process depends largely on the type of wood and its condition.

Types of Wooden Floors and Their Compatibility with Sanding

1. Solid Hardwood Floors

Solid hardwood floors are the most compatible with gold coast floor sanding. These floors consist of solid wood planks, which means they can be sanded multiple times throughout their lifespan. Whether it’s oak, maple, or cherry, solid hardwood responds exceptionally well to sanding, making it an ideal candidate for restoration.

2. Engineered Wood Floors

Engineered wood floors have a veneer of real wood on top of a plywood or high-density fiberboard (HDF) core. The thickness of the veneer determines if gold coast floor sanding is suitable. Thicker veneers (typically over 2-3 mm) can handle light sanding, but thinner veneers may not withstand the process without damage. It's crucial to assess the veneer thickness before proceeding.

3. Parquet Floors

Parquet floors, known for their intricate geometric patterns, are also suitable for gold coast floor sanding. However, the process requires extra care to maintain the design integrity. Professional sanding ensures even results without compromising the delicate structure of parquet layouts.

4. Bamboo Floors

Bamboo flooring, although technically a grass, is treated similarly to hardwood. Strand-woven bamboo is more durable and can handle gold coast floor sanding effectively. However, traditional bamboo floors are softer and may require specialized techniques to avoid damage during sanding.

5. Laminate Floors

Laminate floors are not real wood; they consist of a photographic layer that mimics wood on top of a composite base. Gold coast floor sanding is not suitable for laminate floors as the sanding process would strip away the top layer, exposing the core material underneath. For laminate flooring, replacement is often the better option.

Factors to Consider Before Sanding

1. Floor Thickness

The thickness of the wooden floor determines how many times it can be sanded. Thicker floors allow for multiple sanding sessions, while thinner surfaces may only handle one or two before risking structural damage.

2. Condition of the Floor

Extensively damaged floors with deep gouges, warping, or water damage may require more than just sanding. In some cases, partial replacement of boards might be necessary before sanding and refinishing.

3. Type of Finish

Certain finishes, like aluminum oxide or ceramic-based coatings, are more challenging to sand down. Specialized equipment and techniques may be required to remove these tough finishes effectively.

Benefits of Gold Coast Floor Sanding

Restores Natural Beauty: Removes surface imperfections, revealing the wood's original charm.

Extends Lifespan: Regular sanding can prolong the life of wooden floors by preventing further damage.

Improves Indoor Air Quality: Eliminates dust, allergens, and mold trapped in old finishes.

Increases Property Value: Well-maintained wooden floors are a desirable feature for potential buyers.

Conclusion

In summary, gold coast floor sanding is suitable for many types of wooden floors, particularly solid hardwood, engineered wood with thick veneers, parquet, and strand-woven bamboo. However, it is not recommended for laminate flooring and requires careful consideration for traditional bamboo and engineered floors with thin veneers.

Before undertaking any floor sanding project, consulting with professionals is advisable to ensure the right approach for your specific flooring type. This not only preserves the integrity of the wood but also guarantees the best possible results in restoring your floor's natural beauty.

0 notes

Text

How to Maintain Your PVC Laminates for a Long-lasting Shine

PVC laminates have become a popular choice for modern interiors due to their durability, aesthetic appeal, and ease of maintenance. Whether you have used them on furniture, walls, or kitchen cabinets, proper upkeep ensures they retain their shine and longevity. If you're looking for ways to maintain your pvc laminate surfaces, this guide will provide expert tips and tricks to keep them looking brand new for years.

Why Choose PVC Laminates?

PVC laminates are versatile and highly durable. They offer a sleek and sophisticated finish while being resistant to moisture, heat, and daily wear. Many homeowners and designers prefer pvc laminate because of its affordability and long-lasting performance. Moreover, brands like Amulya Mica Laminates provide a wide variety of finishes, including fabric laminate texture, 1 mm laminate, and high-gloss options, making them a premium choice for interior décor.

7 Essential Tips to Maintain PVC Laminates for a Lasting Shine

1. Regular Cleaning is Key

Dust and dirt can make laminates look dull over time. Wipe the surface regularly with a soft, damp microfiber cloth to remove dust and prevent scratches. Avoid using abrasive scrubbers or steel wool, as they can damage the surface.

2. Use Mild Cleaning Solutions

To maintain the shine of pvc laminate, use a mild soap solution or a mixture of water and vinegar. Avoid harsh chemical cleaners as they can strip the laminate's protective layer.

3. Avoid Excess Water and Moisture

Although pvc laminates are moisture-resistant, prolonged exposure to water can weaken the adhesive. When cleaning, always use a slightly damp cloth rather than soaking the surface. Dry the area immediately after wiping to prevent water damage.

4. Protect Against Scratches

PVC laminates can resist scratches to a great extent, but they are not entirely scratch-proof. Use coasters under hot utensils, avoid cutting directly on laminated surfaces, and keep sharp objects away from furniture finished with Best Laminates in India.

5. Prevent Heat and Sunlight Damage

Direct exposure to sunlight can cause the laminate color to fade over time. If possible, install blinds or curtains in areas where sunlight directly hits your laminated surfaces. Additionally, avoid placing hot appliances like irons or cooking pots directly on pvc laminate surfaces to prevent heat damage.

6. Remove Stains Immediately

Spills and stains should be cleaned immediately to avoid permanent marks. For stubborn stains, use a mild detergent or a laminate-safe cleaner. If ink or grease marks appear, a small amount of baking soda mixed with water can help remove them without causing damage.

7. Polishing for Extra Shine

To restore the original shine of your pvc laminate, apply a specialized laminate polish occasionally. However, avoid oil-based polishes, as they can leave a sticky residue and attract more dust.

Choosing the Right Laminates for Long-Term Durability

When selecting laminates, opting for high-quality products ensures better longevity and shine. Amulya Mica Laminates offers a range of premium laminates, including fabric laminate texture, 1 mm laminate, and many other decorative options suitable for modern interiors. Investing in the Best Laminates in India guarantees durability and minimal maintenance efforts.

Common Mistakes to Avoid While Maintaining PVC Laminates

Using Harsh Chemicals: Avoid using strong acids or bleach-based cleaners, as they can dull the laminate’s shine.

Scrubbing Too Hard: Excessive force can cause scratches and wear down the protective layer.

Neglecting Regular Maintenance: A little daily care goes a long way in keeping pvc laminate looking new.

Ignoring Water Spills: Prolonged water exposure weakens the bond between the laminate and the underlying surface.

Final Thoughts

Maintaining pvc laminates is simple and requires just a few mindful steps. By following these maintenance tips, you can ensure that your laminated surfaces retain their shine and durability for years. Whether you choose 1 mm laminate, fabric laminate texture, or other premium finishes from Amulya Mica Laminates, proper care will help them stay as good as new.

Looking for the Best Laminates in India? Explore the wide range of pvc laminate collections at Amulya Mica and give your interiors a lasting and elegant finish!

By implementing these simple maintenance practices, your PVC laminates will remain in top condition, making your interiors look stylish and well-maintained over time.

#pvc laminate#Best Laminates in India#1 mm laminate#fabric laminate texture#amulya mica laminates#laminate designs#advance pvc laminate#0.8 mm laminate#latest mica design#latest laminates design#premium laminates#buy laminates online

0 notes

Text

1 mm laminate price

Ogaan Laminates offers competitive 1 mm laminate prices, ensuring high quality and affordability for your interior design projects. Their extensive collection includes a variety of textures and patterns, perfect for enhancing any space. Discover the best in durability and style with Ogaan Laminates’ exceptional 1 mm laminate options

0 notes

Text

Secrets to Making the Perfect Croissant Like a Professional Pastry Chef

A flaky, buttery croissant is one of the most iconic pastries in the world. While it may seem like a simple breakfast treat, achieving that perfect balance of crispiness on the outside and a soft, airy interior requires skill, patience, and technique. Whether you're an aspiring baker or an experienced cook, understanding the secrets of a Professional Pastry Chef can help you master the art of making the perfect croissant at home.

1. Choosing the Right Ingredients

The quality of ingredients plays a crucial role in making perfect croissants. A Professional Pastry Chef always emphasizes:

Flour: Use high-protein bread flour to give the dough strength and elasticity.

Butter: Always use European-style butter (with at least 82% fat) for a richer taste and better lamination.

Yeast: Active dry yeast or fresh yeast ensures proper fermentation and rise.

Milk & Sugar: These ingredients contribute to the dough’s flavor and tenderness.

Using top-quality ingredients enhances the texture and taste of your croissants, making them bakery-worthy.

2. Mastering the Dough Preparation

A good croissant starts with a well-prepared dough. Follow these key steps for success:

Mixing & Kneading

Combine the flour, sugar, salt, yeast, and milk in a stand mixer or by hand.

Knead the dough until it becomes smooth and elastic but not overly stiff.

Allow it to rest for at least 2 hours in the fridge to develop gluten structure and flavor.

Pro Tip: Avoid over-kneading, as it can make the dough tough and difficult to laminate.

3. The Art of Laminating the Dough

Lamination is what creates the beautiful, flaky layers in a croissant. This step requires precision and patience.

How to Laminate Like a Professional Pastry Chef

Prepare the Butter Block: Flatten cold butter between parchment paper into a thin, even layer.

Encasing the Butter: Roll out the dough into a large rectangle and place the butter inside.

Folding & Rolling: Perform a book fold or letter fold, rolling the dough out and folding it over itself multiple times.

Chilling Between Folds: Refrigerate the dough for 30 minutes between each fold to maintain butter integrity and prevent melting.

A Professional Pastry Chef ensures that each layer remains distinct, leading to flawless flakiness when baked.

4. Shaping & Proofing the Croissants

Cutting & Shaping

Roll out the laminated dough to about 3-4 mm thickness.

Cut into long triangular shapes with a sharp knife for a professional look.

Gently roll each triangle from base to tip, ensuring a tight but not forced roll.

Proofing for Maximum Fluffiness

Proper proofing is crucial for achieving light, airy croissants. Follow these steps:

Place shaped croissants on a baking tray with space to expand.

Cover with a damp cloth and proof at 24-26°C (75-78°F) for about 2-3 hours until doubled in size.

Avoid excessive heat, as it may melt the butter layers.

A Professional Pastry Chef always ensures proper fermentation for the perfect airy texture.

5. The Perfect Egg Wash & Baking Technique

Applying the Egg Wash

A shiny, golden crust is achieved by applying an egg wash before baking.

Whisk together one egg yolk and a tablespoon of milk.

Gently brush the wash over the croissants, ensuring even coverage.

Avoid excess wash pooling at the base, as it may prevent even rise.

Baking Like a Professional Pastry Chef

Preheat the oven to 200°C (400°F).

Bake croissants for 18-20 minutes or until golden brown.

Rotate the tray halfway through baking for even coloring.

Pro Tip: A Professional Pastry Chef often bakes croissants at a slightly higher initial temperature (220°C/425°F for 5 minutes) to encourage a strong rise before lowering it to 190°C/375°F for even cooking.

6. Final Touches & Serving

Once baked, let croissants cool slightly before serving. Enjoy them fresh with:

Classic butter and jam

Nutella or almond filling

Savory fillings like cheese and ham

To maintain freshness, store croissants in an airtight container for up to 2 days, or freeze them for later use.

Conclusion

Making the perfect croissant requires patience, precision, and practice—all qualities of a Professional Pastry Chef. From choosing high-quality ingredients to mastering lamination and proofing, every step plays a crucial role in achieving flaky, buttery croissants.

By following these expert tips and techniques, you can create authentic, bakery-style croissants right in your kitchen. Whether you're a passionate home baker or aspiring professional, mastering this skill will take your pastry game to the next level! Now, put on your chef’s hat and start baking like a Professional Pastry Chef—your perfect croissant awaits!

0 notes

Text

Exploring the Construction Glass Market in Asia Pacific: Trends, Sizes, and Leading Companies

The construction landscape in the Asia Pacific region is evolving rapidly, driven by urbanization, technological progress, and the demand for sustainable building solutions. Among the key materials transforming modern architecture is construction glass. Valued for its strength, energy efficiency, and design flexibility, construction glass has become a cornerstone for innovative building designs. This blog offers insights into market trends, glass sizes, and major manufacturers contributing to this dynamic sector.

The Growing Construction Glass Market

The Construction Glass Market was valued at USD 112.0 billion in 2024 and is projected to reach USD 144.3 billion by 2029, growing at a 5.2% CAGR from 2024 to 2029. This impressive growth underscores the increasing adoption of glass in modern construction projects across the Asia Pacific region.

Why Construction Glass is in High Demand in Asia Pacific

The Asia Pacific region is witnessing a surge in construction activities fueled by economic growth, government-led infrastructure projects, and rising urbanization. As construction glass plays a dual role—enhancing both the aesthetics and functionality of buildings—it has become a preferred material for residential, commercial, and industrial projects.

Architects and builders appreciate construction glass not just for its beauty but for its ability to improve energy efficiency and provide sustainable solutions.

Key Sizes and Applications of Construction Glass

Construction glass comes in a variety of sizes to meet diverse architectural needs. Typical sizes include:

Standard Sizes: Dimensions such as 6 ft x 8 ft (1830 mm x 2440 mm) and 8 ft x 10 ft (2440 mm x 3050 mm) are commonly used.

Custom Sizes: Tailored dimensions are often required for unique design elements like large façades and curtain walls.

Thickness Options: Glass thickness ranges from 3 mm to 19 mm, with thicker glass used for safety, structural integrity, and noise reduction.

Different types of glass—including tempered, laminated, and insulated glass—address specific requirements such as thermal efficiency, safety, and soundproofing.

Emerging Trends in Construction Glass

1. Energy-Efficient and Smart Glass

Energy conservation is a top priority in modern construction. Smart glass technologies, such as electrochromic and thermochromic glass, are becoming popular for their ability to regulate transparency and reduce energy consumption.

2. Sustainability Initiatives

As governments promote eco-friendly construction, demand for green building materials is rising. Energy-efficient construction glass that reduces environmental impact is gaining traction.

3. Innovative Coatings and Surface Treatments

Advanced coatings, such as anti-reflective and self-cleaning treatments, enhance the functionality and lifespan of construction glass. These solutions are particularly valuable for high-rise buildings.

4. Safety and Security Focus

Strict safety regulations are driving the use of laminated and toughened glass, which provide better protection against impact and environmental hazards.

Top Construction Glass Manufacturers in Asia Pacific

Several leading companies are driving innovation in the construction glass sector:

AGC Inc. (Japan): Offers a wide range of architectural glass products with cutting-edge coatings and treatments.

NSG Group (Japan): A leader in solar control and thermal insulation glass technologies.

Saint-Gobain (France): Known for innovative and sustainable glass solutions that support modern construction needs.

Guardian Industries (US): Renowned for advanced glass products used in commercial and residential projects.

Sisecam (Turkey): Specializes in flat glass and energy-efficient solutions.

SCHOTT AG (Germany): Offers high-quality specialty glass for architectural applications.

Central Glass Co., Ltd. (Japan): Provides innovative glass solutions for construction and automotive sectors.

China Glass Holdings Limited (China): Provides a diverse range of glass solutions for construction applications.

Vitro (Mexico): Known for its extensive portfolio of architectural and industrial glass products.

Notable Regional Manufacturers

Local manufacturers are playing a vital role in advancing the construction glass market in Asia Pacific:

Taiwan Glass Ind. Corp.: Specializes in high-performance architectural glass.

China Glass Holdings Limited: Provides a diverse range of glass solutions for construction applications.

Viridian Glass (Australia): Known for its energy-efficient and decorative glass products.

Looking Ahead: The Future of Construction Glass in Asia Pacific

The construction glass market in Asia Pacific is poised for growth, driven by advancements in technology and a strong push for sustainable development. The adoption of smart glass, innovative coatings, and eco-friendly solutions will redefine modern architecture.

As governments and industries alike prioritize green buildings, the demand for advanced construction glass is expected to soar. The increasing vertical growth of cities and intricate architectural designs will only amplify the importance of this versatile material.

Get deeper insights, download PDF brochure :

Construction glass is playing a pivotal role in shaping the future of architecture in Asia Pacific. From standard sizes to custom solutions, it offers unmatched versatility for various building types.

As leading global and regional manufacturers continue to innovate, construction experts can look forward to more options that combine functionality, sustainability, and aesthetics. The region’s architectural landscape is set to become even more dynamic, thanks to advancements in construction glass.

#ConstructionGlassTrends#AsiaPacificConstruction#SmartBuildingMaterials#SustainableArchitecture#ConstructionGlassManufacturers#ModernBuildingDesigns#EnergyEfficientGlass

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer Excellent Finish: This TV unit is made using European engineered wood with 15 mm thickness for a sturdy finish. Scratch Resistant: The surface is resistant to scratches, keeping your unit in pristine condition. Laminated Base: The laminated base on the TV unit adds to the aesthetic of your home. Dust Resistant PVC Band: The PVC banding keeps the dust away from the unit, enhancing the visual appeal. 1 Scratch Resistant: 2 Laminated Base: 3 Dust Resistant PVC Band: Termite Resistant: The make of this TV unit ensures the termites stay away from it and your home stays termite-free. Tested for Quality: This TV unit has passed 15+ quality checks to offer you the best at the best price. Premium Quality. Great Value. Welcome to the world of Solimo - a place where premium quality and great value go hand in hand. Every Solimo product is carefully built to deliver exceptional quality. Right from the materials used, to detailed quality checks, to thoughtful improvements, quality is at the core of everything we do. Product Dimensions:180 x 39.5 x 61 cms Number of Shelves: 7 Shelves Assembly Instructions: Installed by seller Product Weight: 38 KG Special Features: - Made with 15 MM European standard engineered wood - Being termite resistant, the product also ensures longevity and durability. Featuring full edging and secured with lamination, prevents the build-up of moisture. Also, it is easy to clean [ad_2]

0 notes

Text

What is the cost of plywood per sheet in Bangalore?

An essential material, plywood is used widely in interior design, furniture manufacturing, construction, automotive, and packaging. Plywood, famous for its strength, flexibility, and visual appeal, has become a well-known choice for numerous purposes. Understanding the components influencing plywood sheet prices in Bangalore is essential if you expect to purchase plywood to make wise choices.

Even though it is difficult to lay out the exact cost per sheet without considering specifics, this article outlines the factors that influence plywood costs, the kinds of plywood that are accessible, and advice for buying plywood in Bangalore.

Factors That Influence the Cost of Plywood

Several variables affect the plywood price in Bangalore. The following are the main factors that affect the cost:

1. Type of Plywood

There are several varieties of plywood, each planned for a specific use. The three most famous sorts of plywood are decorative, marine, and business. Every type has extraordinary qualities and costs. For example, marine plywood is commonly more expensive than commercial plywood because of moisture obstruction and suitability for areas that experience a great deal of water.

2. Grade and Quality

Plywood sheets' quality, look, and sturdiness are utilized to grade them. Their appropriateness for different applications is shown by grades like MR (Moisture Resistant), BWR (Boiling Water Resistant), and BWP (Boiling Waterproof). Since higher-grade plywood has better quality and sturdiness, it ordinarily costs more.

3. Thickness of the Sheet

Their thickness mainly determines the expense of plywood sheets. Standard thicknesses are between 4 and 25 mm, and thicker sheets cost more. Whether the thickness is picked for wall paneling, deck, or cabinets it relies upon the intended application.

4. Core Material

Plywood price in Bangalore is also influenced by its core material. Compared to plywood created with softwood cores, plywood with hardwood cores is typically more durable and costly. Furthermore, plywood from sustainable or environmentally favorable sources could cost more.

5. Brand and Certification

Generally, reputable plywood companies with certificates like ISI or FSC (Forest Stewardship Council) are more expensive and dependable. Quality and environmental sustainability are crucial considerations for many purchasers, and these certificates guarantee both.

6. Finish and Decorative Features

Plywood costs more in Bangalore for veneers, laminates, or decorative finishes than plain sheets. These characteristics improve the plywood's visual attractiveness, making it appropriate for furniture or interior design tasks.

7. Market Demand and Supply

Plywood cost in Bangalore can be impacted by changes in supply and demand in a busy metropolis like Bangalore. Price fluctuations are frequently determined by local construction activity and seasonal trends.

Types of Plywood Available in Bangalore

The varied market in Bangalore provides plywood solutions designed to satisfy various requirements. The main types are as follows:

1. Commercial Plywood: It is widely used for furniture and cabinetry because it is affordable and adaptable. It works best indoors, with less chance of exposure to water or harsh environments.

2. Marine Plywood: Marine plywood, frequently used in kitchens, baths, and outdoor applications, is ideal for damp or humid conditions due to its strong water resistance.

3. BWP and BWR Plywood: Kitchens and other damp spaces are perfect for Boiling Waterproof (BWP) and Boiling Water Resistant (BWR) plywood because of their strength and water resistance.

4. Waterproof Plywood: A robust and adaptable wood product, waterproof plywood is made to withstand dampness and water damage. It is perfect for outdoor furniture, kitchen cabinets, and bathrooms because it has water-resistant adhesives and treated layers. You can also search for waterproof ply prices.

5. Decorative Plywood: With its eye-catching veneers or laminates, it is widely used to create fashionable furniture and interior design. It would help if you also searched for waterproof ply prices.

Tips for Buying Plywood in Bangalore

Take into account the following advice to make the best choice possible:

Assess Your Needs: Determine the precise specifications for your project, such as the kind, thickness, and finish of the plywood. For instance, use marine plywood if you're building cabinets for a humid location.

Compare Prices: To evaluate costs and products, visit several online stores or websites. This guarantees you meet your quality standards and receive value for your money.

Check Certifications: Always look for ISI or FSC certifications to ensure the plywood is genuine and high-quality. Guarantees or warranties are frequently included with certified products.

Conclusion

Type, quality, thickness, and brand are a few factors that influence plywood sheet prices in Bangalore. Realizing these components will empower you to make a superior informed buy that fits your task's necessities and financial plan. The large selection of plywood options in Bangalore ensures that you'll find something that fulfills your needs, whether building new furnishings or redesigning your home. To settle on the best choice for your venture, focus on quality, assess options, and seek expert advice.

#commercial ply board#bangalore plywood#cost of plywood board#plywood cost in bangalore#plywood factories in bangalore#best plywood in india#plywood company in bangalore#plywood price bangalore#best plywood for wardrobe#plywood sheet cost in bangalore

0 notes